New Product Implementation - your guarantee for optimized scalability

Working closely with the heavy-weights in the defense industry, employing a thorough New Product Implementation-process (NPI) is your guarantee for...

2 min read

Multicut Blog Author Aug 1, 2025 3:03:00 PM

The objective was clear: Raytheon wished to ramp up the delivery rate of a selection of their standard ship-launched missiles to more than double. The challenge was almost as clear: whom to partner up with to achieve such an end? Questions needed to be asked regarding automation, precision, price, and quality. Luckily, Multicut proved to be the answer to all those questions.

Key to the flourishing partnership between Multicut and Raytheon is our flawless production setup, M·Sys™, ensuring endless scalability opportunity without ever compromising the supreme quality and precision of the delivered components. These are exactly the qualities that make us an ideal supplier for the fluctuating demands of the defense industry.

The ESSM® (Evolved SeaSparrow Missile) Block II program is a short to medium range, ship-launched, dual-mode guided missile designed to enhance defense capabilities against all modern naval threats. The Surface-To-Air/Surface-To-Surface missile program is an evolution of the original ESSM® program that has been in place since 1968, making it the longest running cooperative smart defense initiative in the history of NATO.

The system offers defense at sea to participating navies as well as third-party customers and is developed and employed by the U.S., NATO partner nations, and Australia, and the NATO SEASPARROW Consortium is expanding, which calls for a rapid and drastic ramp-up in production.

Multicut has contributed to the production of 22 machined parts for the ESSM Block II program and the scalability offered by the M·Sys™ has played a vital role and will continue to do so, as it eliminates human risk factors, whatever the scale of the production.

We are not simply the supplier of Raytheon; we engage in an active partnership, and this particular partnership is a textbook example of synergy maximization. We got onboard early in the design and production phase, and through the reciprocal creativity of the project, we were able to leverage our fully automated manufacturing facilities to their fullest potential.

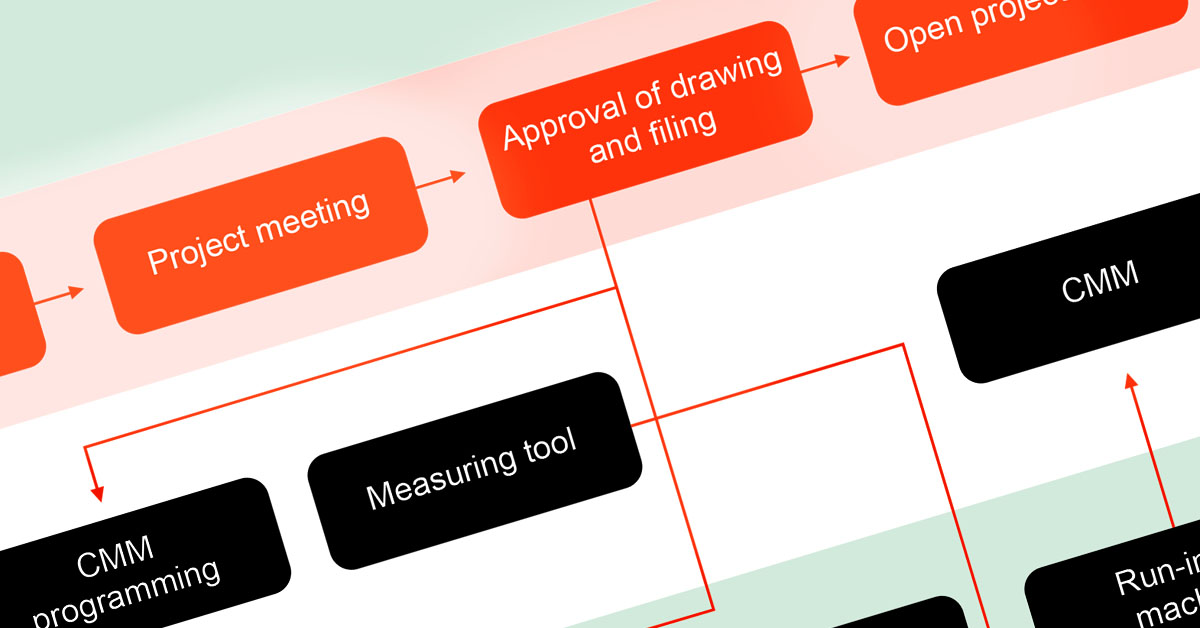

Together, we had a total rethink of the production process. Not only did our fully automated M·Sys™ allow us to considerably reduce the setup time for every item in our production lines, but it also allowed us to manufacture all parts in one single setup, ensuring a seamless ramp-up of the production.

With production facilities in Vildbjerg (Denmark) as well as in Fort Collins (Colorado, the United States), we were able to accommodate several visits from Raytheon, giving them clear indications of the progress. Much to the delight of the representatives, they could themselves observe the efficiency of the setup, reducing the costs per unit by more than 50%, making Multicut a more attractive option than Raytheon’s former suppliers in terms of scalability, quality as well as price. The costs of some items we reduced to as little as a fourth of the price offered by other suppliers, making the partnership between Multicut and Raytheon a no-brainer.

A word from the ESSM® Director at Raytheon:

”We are happy to endorse Multicut as a partner in innovation and creativity. Their focus on efficient manufacturing, process automation, and robust machining expertise has been invaluable for ESSM® as we pursue efforts to more than double our delivery rate. I certainly would encourage teams to take advantage of their core capabilities early in the design/production phase to maximise the benefits.”

Working closely with the heavy-weights in the defense industry, employing a thorough New Product Implementation-process (NPI) is your guarantee for...

%5B1%5D.jpg)

A European Defense Industrial Strategy (EDIS) was presented after the aggression against Ukraine. The strategy is intended to encourage investments,...

In the world of Greentech, new technologies emerge all the time– with components that have perhaps never been machined before. For inventors and...