An uncompromising ramp-up: Multicut and the ESSM® Block II Program

The objective was clear: Raytheon wished to ramp up the delivery rate of a selection of their standard ship-launched missiles to more than double....

2 min read

Multicut Blog Author : Apr 23, 2025 4:52:29 PM

Working closely with the heavy-weights in the defense industry, employing a thorough New Product Implementation-process (NPI) is your guarantee for optimizing scalability, traceability, security in supply, thus maintaining a superior production flow every time. Our NPI process is an integral part of our Quality Assurance (QA), making it an ideal match for the defense industry.

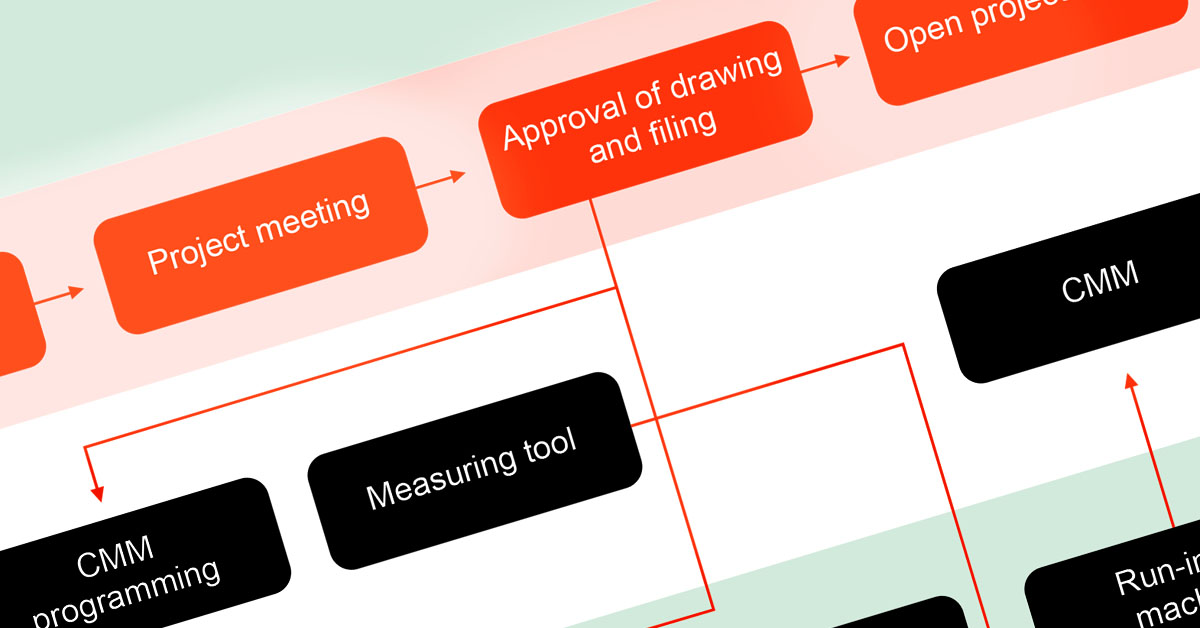

Every time we undertake a new large-scale project – whether from a new or existing customer – we submit the project to a strict protocol before entering it into our production flow. This process is divided into three major phases: the initial, the performing, and the delivering phase. Every step of the process follows a meticulous protocol, ensuring that all skills and knowledge are aligned before finalizing the production plan.

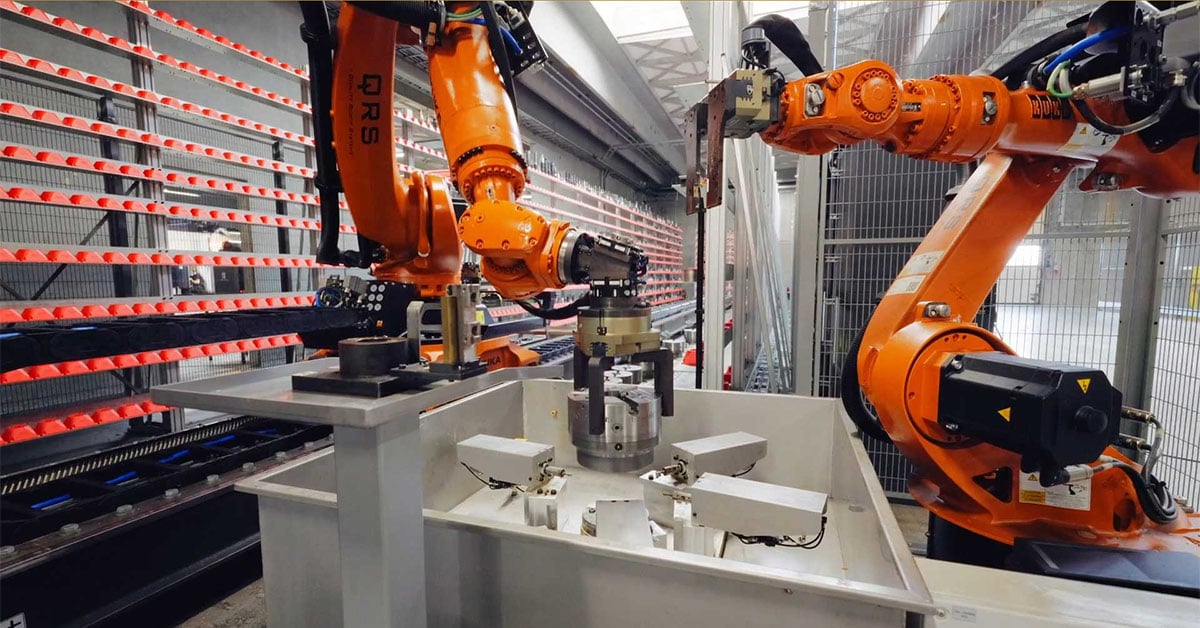

From the knowledge of the customer, through Purchase and Planning, Sales, QA, and Manufacturing Engineering Department (equivalent to PTA), every detail is considered before production begins in our fully automated facilities.

What this means is a thorough assessment of every possible complication throughout the eventual production flow, ensuring seamless scalability, immaculate traceability, and guaranteed security in supply. These are the qualities that have made us an ideal supplier for the defense industry and will continue to do so for years to come.

Once we and our customer have reached an agreement upon the technical drawings for the project, the initial phase is over, and the performing phase begins.

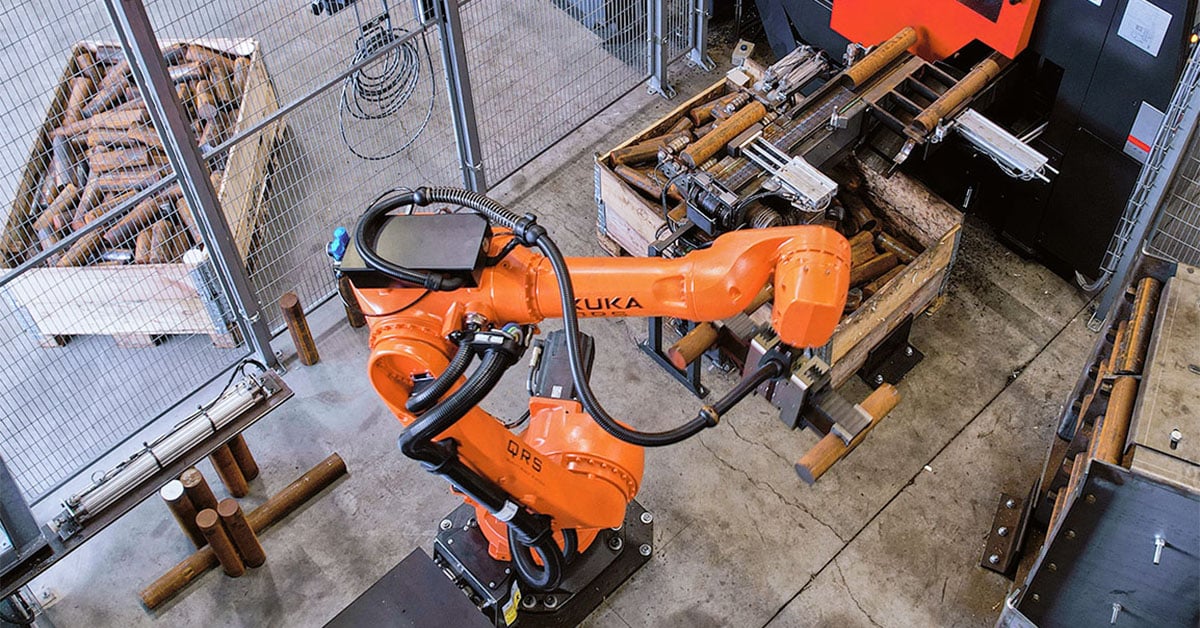

Several processes start simultaneously: In the QA Department, we start programming our Coordinate Measuring Machine (CMM). At this step, applying state-of-the-art technology as part of our fully automated M·Sys™ production philosophy, we are able to optimize the production flow, reducing the waste rate to 0%, while the ability for replication is at a rate of 100% accuracy – a perfect fit for the defense industry, where precision is paramount.

In the Manufacturing Engineering Department (or PTA), the required fixtures are procured or developed. Using advanced Computer Aided Design (CAD) software, the customers' initial technical drawings are perfected, and by employing Computer Aided Manufacturing (CAM) software, we make an ultra-precise production plan, ensuring that every required tool is available and that every step of the production flow is optimized. This is key, as it allows for the project to comply with our fully automated productions facilities, guaranteeing perfection every time.

Meanwhile, in the Purchase and Planning Department, the project is submitted to our Enterprise Resource Planning system (ERP) for two main reasons: traceability and security in supply. Running the project through our ERP system allows us to plan, procure, and localize every required material. We know exactly what is in stock, what needs to be procured, and how it fits into the timeline. This is vital when dealing with industries with extremely strict quality standards like the defense industry. Should any unforeseen obstacle occur with regards to our material suppliers, we can trace any shipment down to the minutest of detail, making sure that no mistake ever goes unnoticed.

Once all the preparations and tests are done in the performing phase, we enter the final phase of delivering. After a thorough review in the Purchase and Planning Department – making sure that everything is setup for the eventual mass production – we are ready for the First Article Inspection (FAI) – a milestone in any production of the standards required in the defense industry.

This is done before the start of any mass production, and our meticulous approach ensures that the FAI is not only subject to external revision by the customer but internal revision as well. Being embedded firmly in our QA Department, our NPI process is our guarantee to our customers that every step of the production flow is optimized and considered down to the smallest detail.

No matter the size of your next project or the complexity, Multicut is here to help. By employing our strict NPI-process, we guarantee that the final product as well as the entire manufacturing setup is optimized, scalable, traceable and 100% impeccable. If you wish to know more about our New Product Implementation process, you can read more here.

The objective was clear: Raytheon wished to ramp up the delivery rate of a selection of their standard ship-launched missiles to more than double....

The ceaseless progression of technology stops for no one - and the industrial landscape makes no exception. With the booming transformation that the...

In an industry where punctuality and timeliness are crucial, there is no room for mistakes. When Multicut forms part of any supply chain, we always...