Boost your profitability and product quality with one-piece flow

The grand idea behind one-piece flow is that each metal component is individually processed and subsequently moved from one workstation to the next...

3 min read

Multicut Blog Author Nov 28, 2025 12:48:32 PM

In late September, representatives of our long-standing partners Raytheon graced our facilities in Vildbjerg, Denmark, with their presence. The occasion: The evaluation of the APQP protocol ahead of the production of highly sophisticated components for the StormBreaker program. Senior Quality Engineer, Thomas Stage-Riis, oversaw proceedings, and he is happy to share some of the findings.

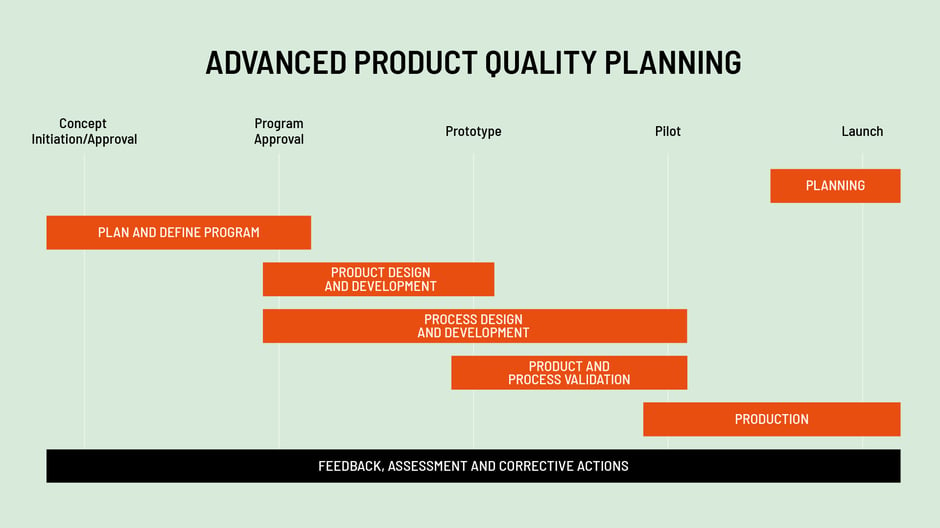

Originally developed for the automotive industry, APQP (Advanced Product Quality Planning) is employed as a meticulous regime to monitor the risks in any given process to ensure flawless execution. Thomas Stage-Riis explains: “There are five main phases: Planning, product design, process development, product/process validation, and improvement. It’s quite simply a matter of considering all the things that could go wrong in any given process. What can we do to avoid these variations, and, if they for some reason occur anyway, how do we identify and correct them?”

In order to be able to make this assessment, you have to be meticulous, because identifying potential risks is not all: “Every single step of the process is mapped and rated according to the level of the risk: How complicated is the risk? How often does it occur in the production setup? And how big is the potential impact? Based on this analysis, we assess the production process and highlight the critical points.”

As in most aspects of life, it is better to be safe than sorry. Stage-Riis explains: “If you want to do this correctly, you have to employ this model before you start the actual production. Otherwise, you only see what you see, and don’t take into consideration all the things that could go wrong, but didn’t go wrong when you did your test run.”

APQP is a continuous process that has to be updated frequently: “From time to time, it happens that we receive notifications from our customers that we have to take into consideration. We might have to switch from one process to another, or something similar, and every time a new variable pops up, you have to update and reconsider the plan.”

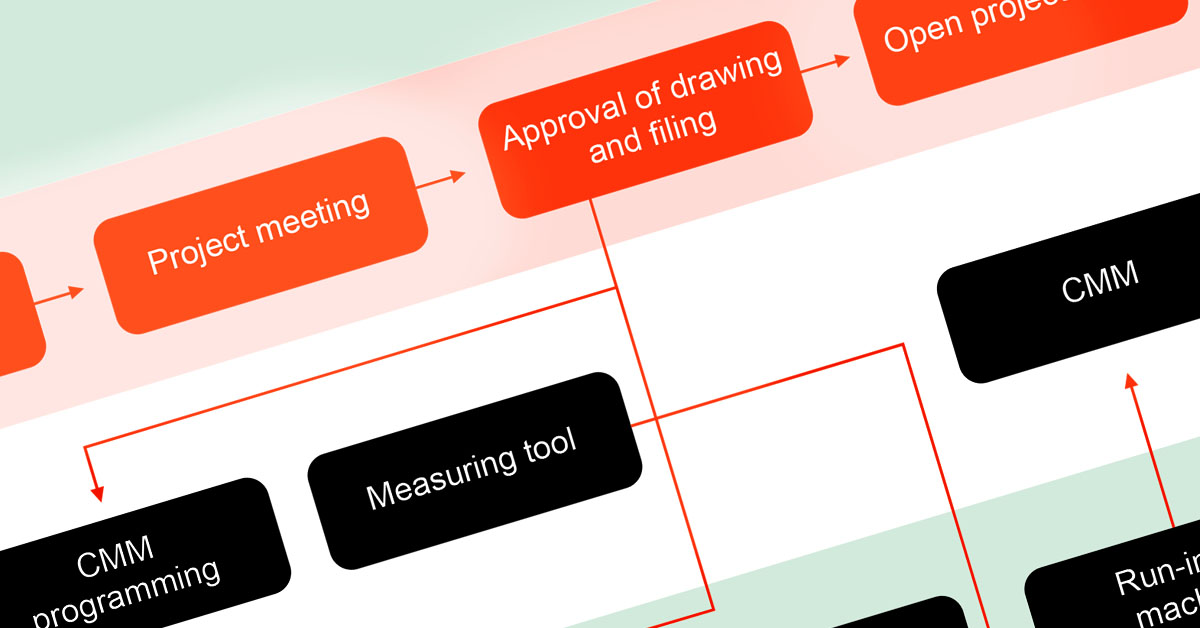

The FMEA’s (Failure Mode and Effects Analysis – further divided into a design and a process phase, DFMEA and PFMEA), the flow chart, and the control plan provide us with the requisite overview, as they indicate the critical points in the production.

“So that’s what we did: We went through the control plan, the flow chart, and every relevant item in the catalogue.”

APQP was developed to meet the demands that every business faces. As Thomas Stage-Riis puts it: “If you are lucky enough to have unlimited funds, then it’s no trick to make a flawless production, but if you’re tied to budget – which, let’s face it, all of us are – you have to come to terms with the fact that risks do occur.”

Complying with APQP would be an extremely time-consuming process if you start from scratch every single time. Fortunately, we have already mapped and assessed the risks in our individual processes, which gives us a strong foundation. This preparation means we can quickly adapt when new variables arise – such as changes in equipment or customer requirements – without compromising quality or timelines. By understanding our processes in detail, we save time, reduce complexity, and maintain consistency across production.

Looking ahead, Stage-Riis is clear about our commitment: “We will continue to apply the same meticulous approach to process planning in the future. If you don’t map the flow, you can’t see where improvements are needed. A well-defined process is the foundation for continuous improvement and reliable delivery.”

Furthermore, it reduces the waste rates considerably. “The higher the waste rate, the more complicated it gets to deliver on time. It’s hopeless to produce 100 items if you only have to deliver 50, because you know you have to discard half of them. It’s just a waste of time and resources; it’s bad business, frankly.”

“Reliability is everything,” Thomas Stage-Riis emphasizes. “APQP is our guarantee for delivering on time, in the right quantity, and at the highest quality – every single time.” In other words: Making a rigorous process assessment and conducting due diligence is our guarantee that whenever you are dealing with us, promises are kept.

The grand idea behind one-piece flow is that each metal component is individually processed and subsequently moved from one workstation to the next...

Working closely with the heavy-weights in the defense industry, employing a thorough New Product Implementation-process (NPI) is your guarantee for...

The objective was clear: Raytheon wished to ramp up the delivery rate of a selection of their standard ship-launched missiles to more than double....