Industry 4.0: The foundation of everything we do

The ceaseless progression of technology stops for no one - and the industrial landscape makes no exception. With the booming transformation that the...

3 min read

Multicut Blog Author : Dec 10, 2025 11:36:10 AM

The next generation is upon us. At Multicut, we take pride in educating highly skilled and independent apprentices, making sure they gain real-life experiences of what it is like to work in our industry.

Ronni Tipsmark is responsible for several of our apprentices, especially our industrial technicians. He knows what he is talking about; he completed his own apprenticeship with us. In 2026, he will celebrate 25 years at Multicut, and today, he is delighted to teach the next generation.

“Right now, we have six apprentices, but in the future, we would like to have eight at a time with a new starting every six months,” Tipsmark explains. “It’s very rewarding for me personally to pass on my knowledge to the new apprentices.”

Among our apprentices is Thomas Strandby. Thomas had been working at Multicut for years before becoming an apprentice. Mostly stationed at the production lines, he served as a link between production and the PTA. We spotted his talent and offered him an apprenticeship. “In the beginning, I was hesitant,” Strandby admits, “I actually declined. I was studying to become an electronics engineer, but I missed seeing the physical result of my labour, so eventually I was convinced.”

Everyone is pleased with his decision, and Strandby is happy to be a part of the team – especially because of our approach to education: “The gap between theory and practice is very small, and that’s extremely satisfying. As apprentices at Multicut, we gain experience from many different aspects of our industry at a very high technical level.”

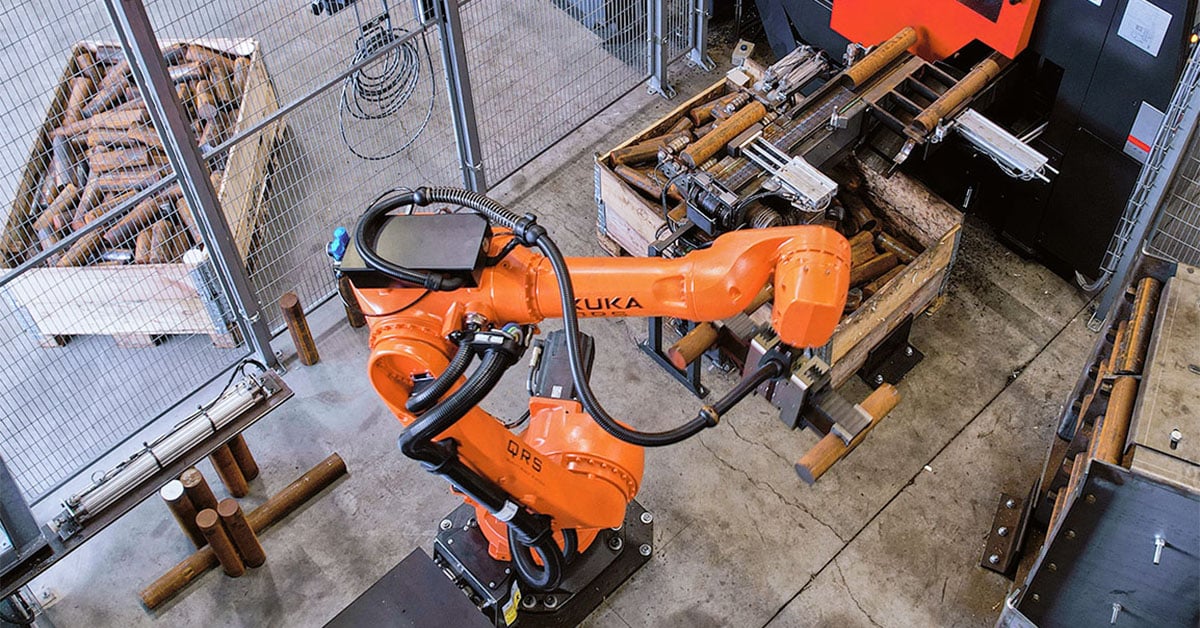

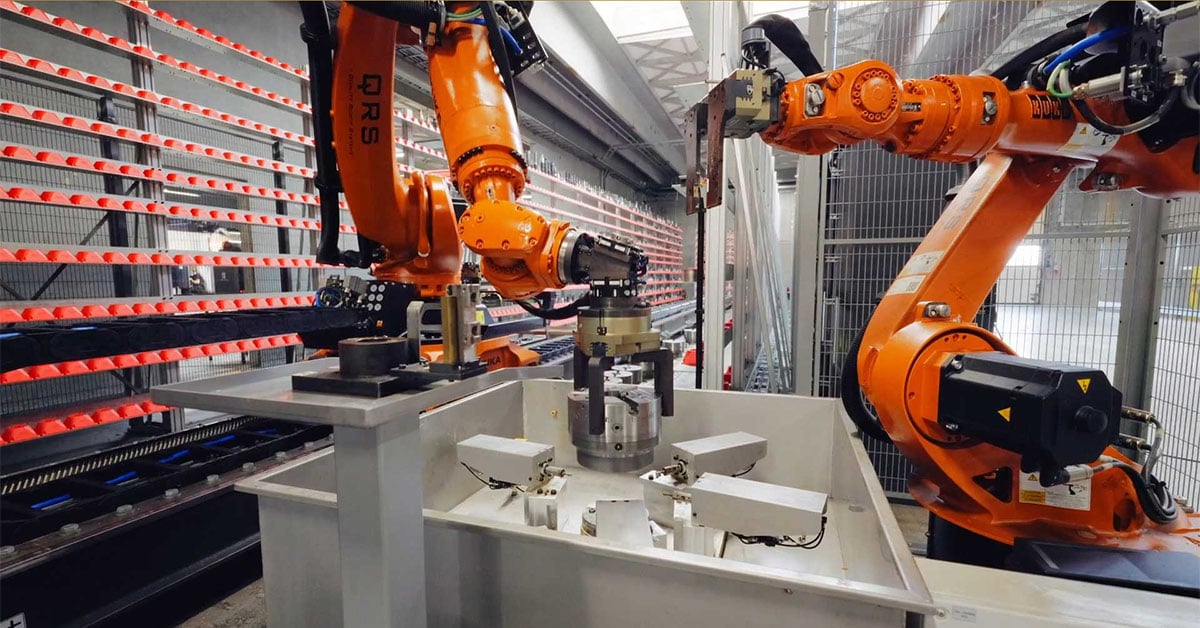

Furthermore, we have the equipment to back up our ambitions – much to the delight of Thomas and his peers: “We have access to a variety of machines that you don’t see often elsewhere – and we’ve got loads of them!” he says with enthusiasm.

Thomas Strandby in action

Thomas Strandby in action

Every expert was once a beginner. Progression takes time, but we are not afraid to throw our apprentices in at the deep end. “When I speak to other apprentices at my school, they are often given less complex assignments,” Strandby explains. “I almost get the impression that their apprenticeship doesn’t really begin until they’re fully trained. At Multicut, it’s different. We’re deeply involved from the start. They encourage us to take chances and make mistakes as long as we learn from them – don’t make the same mistake twice,” Strandby says with a laugh.

Working as an industrial technician is often a solitary undertaking. You spend a lot of time on your own, but at Multicut, sparring and expertise are never far away: “You can always ask for help, and the doors are never shut”. Our huge reservoir of knowledge and experience is at the disposal of the apprentices, and we are more than happy to share it. “When I ask for help, I’m not in the way; everyone here knows that’s all part of the process,” Strandby elaborates.

We encourage our apprentices to take initiative, and Strandby is exemplary in this regard. Together with a fellow student, he signed up for the Danish Championship in 3D printing. “I asked my superiors if I could participate, and they were super supportive. It’s in their best interest that our education is as broad and varied as possible.”

Needless to say, he won the championship.

An apprenticeship at Multicut offers a range of opportunities, and it is not necessarily confined to our facilities in Vildbjerg. As Ronni Tipsmark explains: “We offer our apprentices the opportunity of going to the United States and spend six weeks at Lockheed Martin’s facilities, where the F-35 fighters are assembled. It’s incredibly educational to see something new and to gain first-hand experience.”

Strandby seized this opportunity – a decision that he will never regret: “It was probably the greatest experience of my apprenticeship,” he recalls. “It was super educational and inspiring. We were there to observe all the latest technologies and how the components from all over the world are assembled. Of course, I’m familiar with many of the components we produce ourselves, but you don’t get the bigger picture before you see the final result”.

“When I talk to the other apprentices at my school, their envy is quite visible,” Strandby admits.

Thomas’s time as an apprentice is coming to an end. This spring, he is fully trained – but he has no intention of leaving us any time soon. “It’s definitely my plan to stay put,” he reveals, “as long as they will have me.”

Are you next in line?

The ceaseless progression of technology stops for no one - and the industrial landscape makes no exception. With the booming transformation that the...

In the world of Greentech, new technologies emerge all the time– with components that have perhaps never been machined before. For inventors and...

In an industry where punctuality and timeliness are crucial, there is no room for mistakes. When Multicut forms part of any supply chain, we always...