Our manufacturing setup is your security in supply

In an industry where punctuality and timeliness are crucial, there is no room for mistakes. When Multicut forms part of any supply chain, we always...

3 min read

Multicut Blog Author : May 7, 2024 10:18:09 AM

The ceaseless progression of technology stops for no one - and the industrial landscape makes no exception. With the booming transformation that the industrial sector has undergone over the past few decades, integrating advanced technologies into manufacturing setups has become the new norm. A lot of companies talk about the principles of Industry 4.0, at Multicut, we use them every single day!

The Fourth Industrial Revolution - or Industry 4.0 - has become a reality with the help of digital technologies that have taken over the world. The Internet of Things (IoT), digitization, automation, robotics, sensors, big data, autonomous vehicles, 3D printing, biotechnology, artificial intelligence, and energy storage have all contributed to the progressive development of the industrial sector - shaping it into the reality we know and operate today.

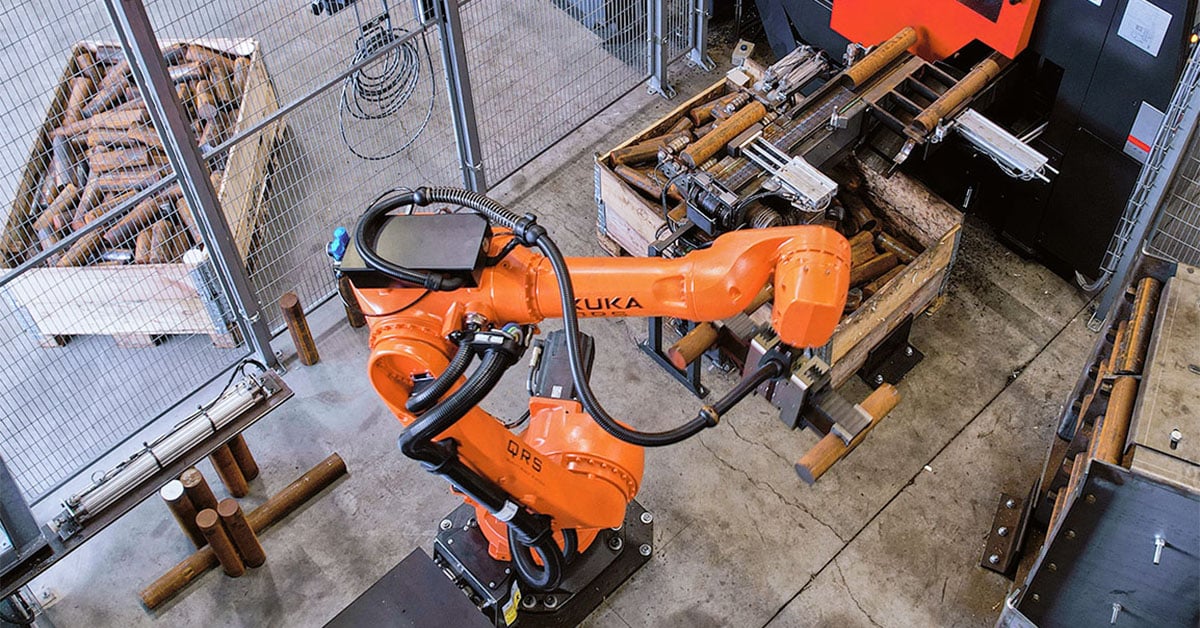

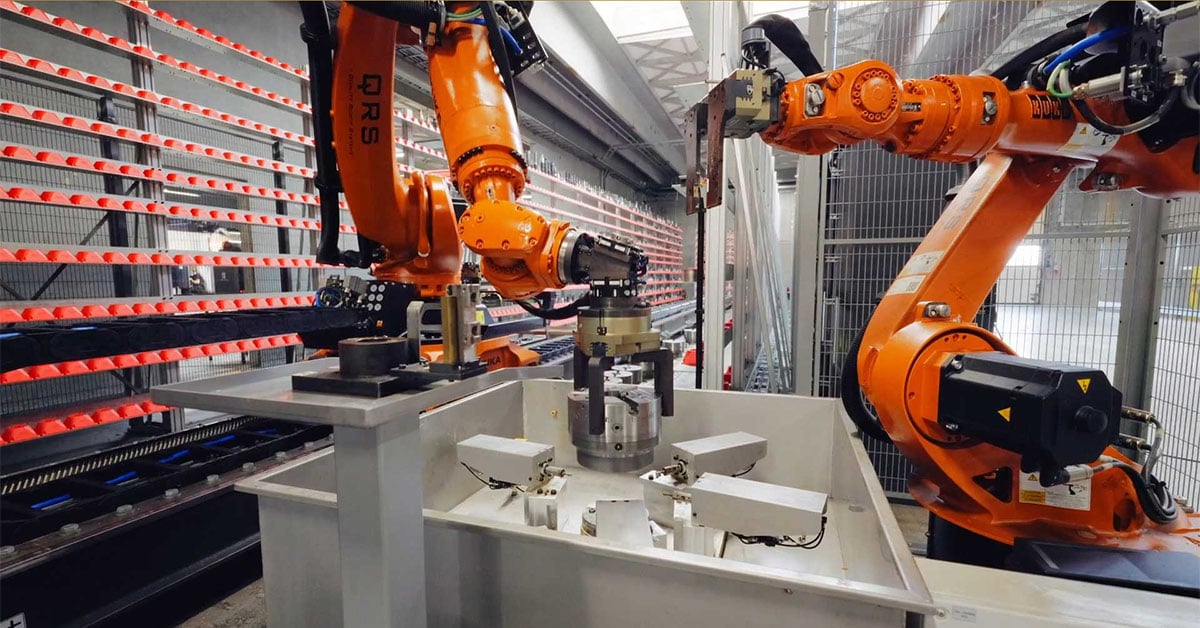

More companies in the industry, are exploring the principles of the fourth industrial revolution, we are already there and have mastered our new production philosophy to perfection. Every day, our production setup runs entirely on the principles of Industry 4.0. Having production lines that are completely steered by robots and CNC (Computer Numerical Control) machines, we manufacture completely uniform entities. Industry 4.0 has enabled us to manufacture products faster, better, and more flawlessly than any human can. Our production philosophy is entirely based on the principles of Industry 4.0 - we call it M·Sys™.

Imagine a factory hall where picking robots, automatic stackers, cutting tools, and fixtures run the entire production. From the raw metal base, through the manufacturing process, to post-production where components are stacked and packed according to their specifications, every aspect of the handling is automated according to the principles of Industry 4.0.

Our employees have created the best possible foundation for our production to run seamlessly. They make sure that every machine and means of digitalization is up-to-date. This way, we may use less manual labor in our production, but our staff members are crucial for the results we deliver. Our M·Sys™ philosophy is the core fuel of our production setup - uplifting our manufacturing to the highest possible quality.

Industry 4.0 allows for flexible manufacturing solutions. Without having to make additional changes to component fixtures, the original workpiece can be processed on every surface which means that the component can be completed in one sequence of operations. We succeed in doing this by milling out one piece of metal without adding unnecessary stress to the metal and without having to weld and scan the welding after completing the production process.

We have come a long way since revolutionizing the manufacturing industry. With today's Internet of Things (IoT), where data sensors improve manufacturers' abilities to design and produce customized components, introducing water and steam in the 1700s production methods seems far away.

However, every single step has been essential steps in today's development. Below you see how +400 years of development have taken the manufacturing industry through the necessary stages, resulting in today's superior industrial setup.

With Industry 4.0 opening new doors and revolutionizing the traditional way of doing industrial manufacturing, it has bettered the conditions for manufacturing scalable metal components to superior standards. We continuously optimize our manufacturing flow and -facilities to stay innovative and contemporary within the metal industry. This way, we demonstrate to our customers that we are willing to exceed market expectations to be the best supplier of high-quality metal components and cutting-edge manufacturing solutions.

Our manufacturing facility is designed and dedicated to accommodate our customer's requests as this is where a great idea turns into a successful product. Our M·Sys™ production philosophy makes us some of the best at scaling and producing flawless lines of metal components. It has several advantages for our customers, as it reduces production costs, and increases the overall speed of production without compromising the quality of the products.

With this flexible manufacturing system, we can deliver ultra-precise, repeatable, and scalable manufacturing solutions at a consistently low and flexible cost. This is why we believe in M·Sys™ and have made it a fundamental part of our production philosophy.

In an industry where punctuality and timeliness are crucial, there is no room for mistakes. When Multicut forms part of any supply chain, we always...

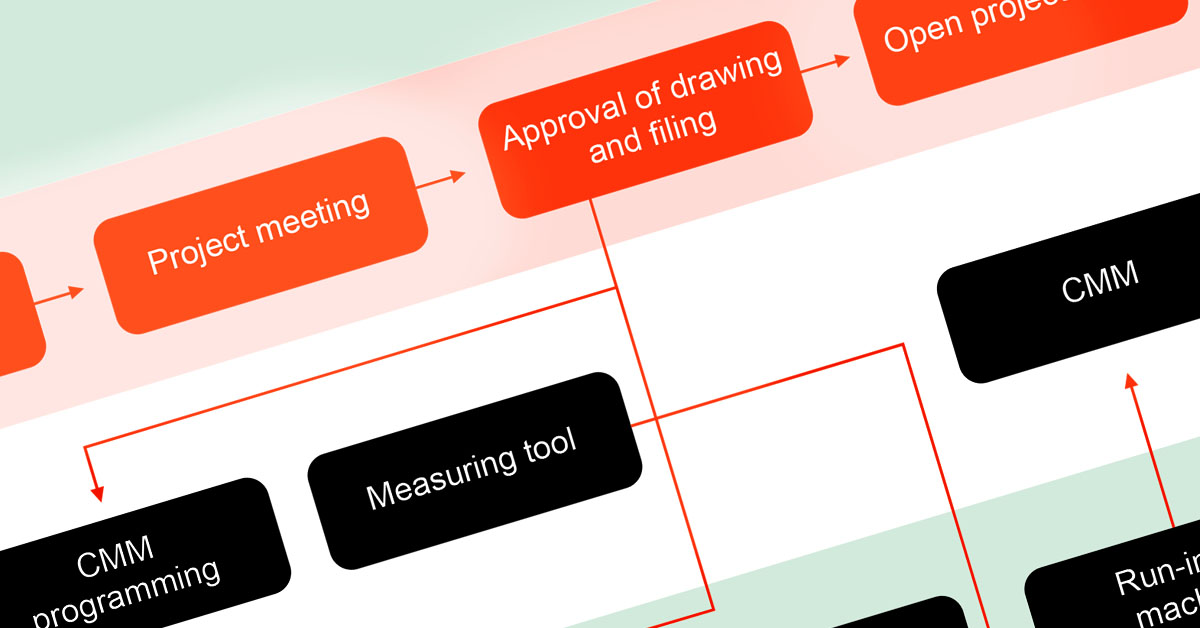

Working closely with the heavy-weights in the defense industry, employing a thorough New Product Implementation-process (NPI) is your guarantee for...

%5B1%5D.jpg)

A European Defense Industrial Strategy (EDIS) was presented after the aggression against Ukraine. The strategy is intended to encourage investments,...