Industry 4.0: The foundation of everything we do

The ceaseless progression of technology stops for no one - and the industrial landscape makes no exception. With the booming transformation that the...

2 min read

Multicut Blog Author : Jun 26, 2024 12:36:12 PM

In an industry where punctuality and timeliness are crucial, there is no room for mistakes. When Multicut forms part of any supply chain, we always guarantee security in supply when customers purchase metal components from us. Whether it is our partners in the Aerospace and Defense industry or our customers in the Greentech sector, we understand the importance of a precise timetable which is why our entire manufacturing setup is shaped to accommodate and assure security in supply on every order. Let us show you how.

Sub-suppliers and suppliers inevitably must have on-time delivery which is why companies increasingly integrate several improving initiatives into their manufacturing setups to ensure security in supply. This way, there will be no hold-ups throughout the supply chain, which is particularly important when working with time-sensitive industries servicing official authorities.

While this is most likely something we can all agree on, companies cannot guarantee security in supply overnight. It takes a substantial investment in your manufacturing procedures and facilities and a change in the general processes. In this blog, we will take you through some of the essential steps, that Multicut made to gain the most cutting-edge manufacturing setup that enables us to guarantee security in supply to all of our customers.

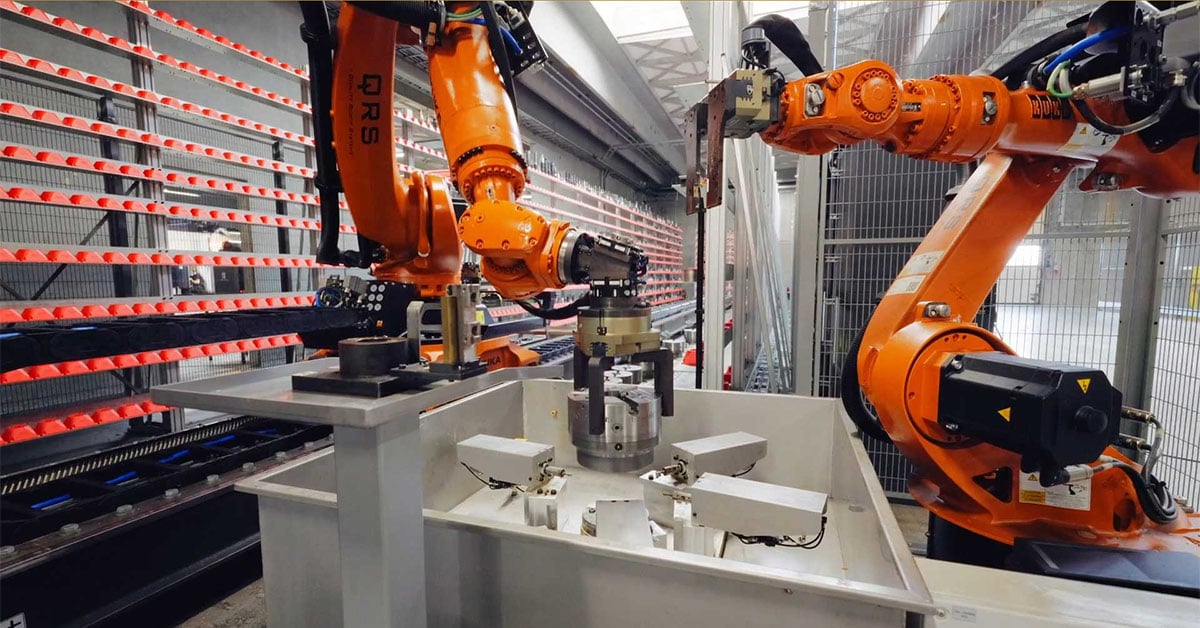

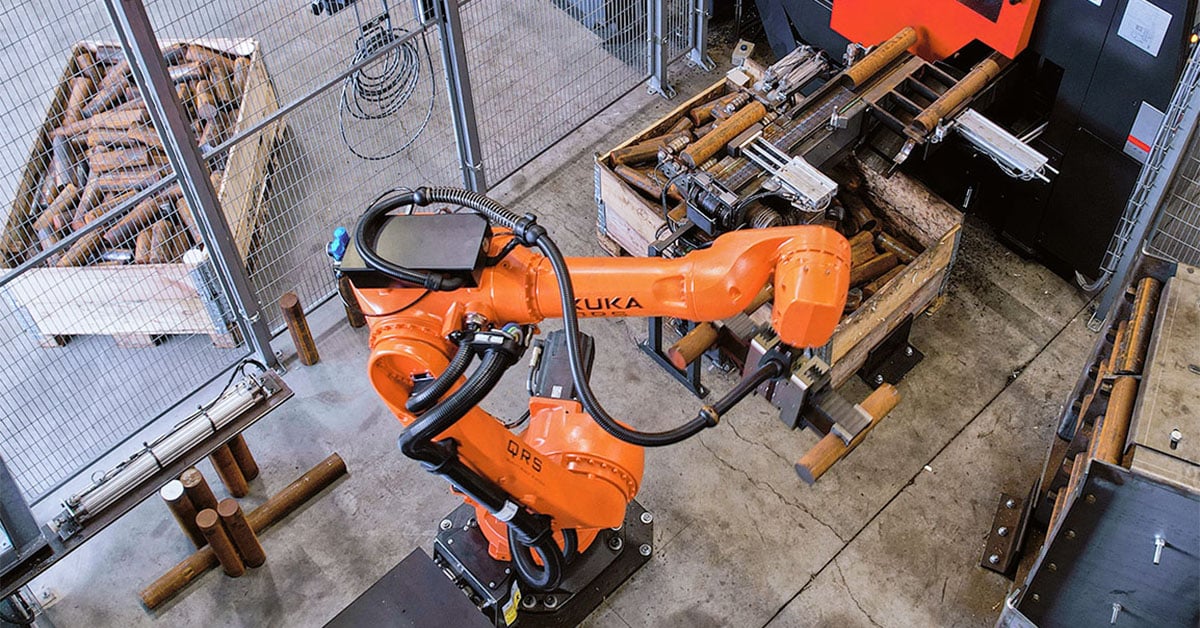

To address the issue of on-time delivery, we have invested in fully automated Industry 4.0 production lines based on cyber-physical technologies, such as the Internet of Things (IoT), that have revolutionized the manufacturing industry altogether. At Multicut, the ambitions were high and we wanted to develop a manufacturing setup that allowed us to manufacture 24/7, independently of any human involvement. Our new manufacturing philosophy, M·Sys™ does just that.

From choosing the right milling tool to transporting the units from one station to another - all manufacturing processes are fully automated. The endless possibilities that M·Sys™ unlocks enable us to pre-define the production time of all projects before we start feeding the machines.

Every aspect of the production that can be predefined is an asset to the product outcome which we will dive further into below.

All raw material is assigned with its own identification code. This is done to ensure that each item is manufactured 100% according to specifications. The same applies to tool blades and fixtures that are also identifiable with their own unique identification code. Each project requires a specific set of tools and fixtures that are specifically chosen for the project at hand. The process of selecting the right tools is completely automated while each fixture is automatically built on-site to accommodate the specific components and tools operating in the manufacturing process.

The means of identification codes further make it possible to use our CNC machines day and night without any production stops as every metal and process is fully categorized and automated avoiding any errors.

To Multicut, delivering and guaranteeing security in supply means that the entire production set-up is customized and designed for 100% automated manufacturing, ensuring on-time delivery every single time. Our ability to deliver security in supply further makes it possible for us to do a production ramp-up without any obstacles. Security in supply has become a commodity in today's industry and is essential to all businesses to maintain a seamless and streamlined supply chain.

Working with time-sensitive industries such as the Aerospace and Defense industry entails that Multicut, as a sub-supplier, must guarantee security in supply. These industries highly depend on an effective supply chain. We have made the necessary investments and will continue to do so to further innovate our manufacturing setup and stay contemporary and competitive as a sub-supplier of manufactured metal components.

The ceaseless progression of technology stops for no one - and the industrial landscape makes no exception. With the booming transformation that the...

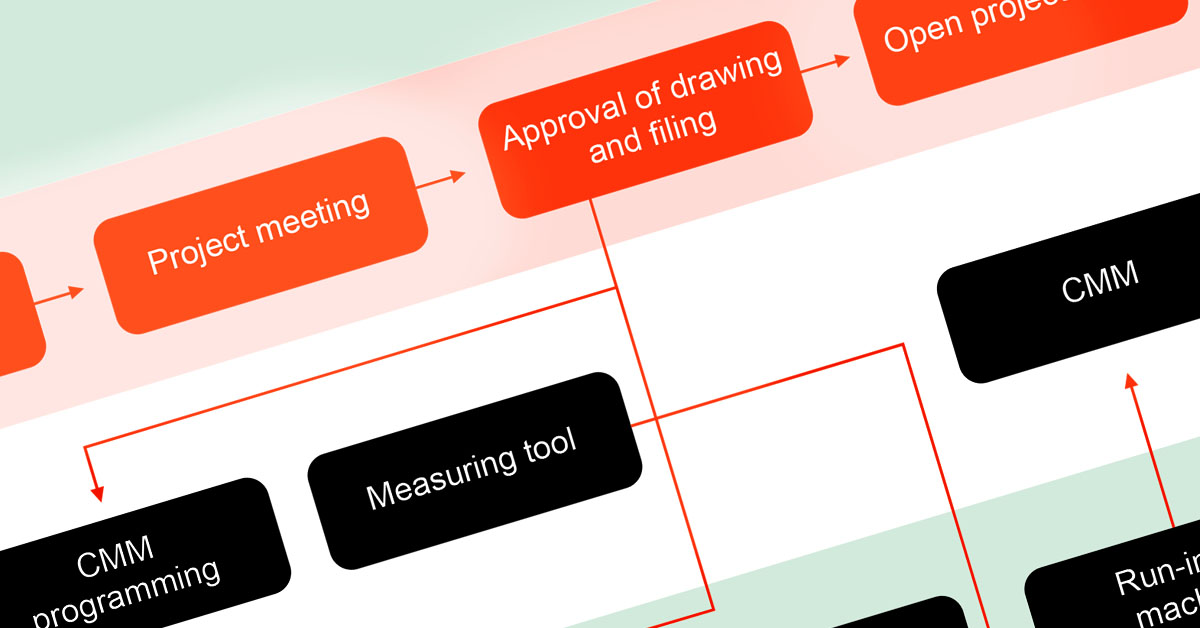

Working closely with the heavy-weights in the defense industry, employing a thorough New Product Implementation-process (NPI) is your guarantee for...

%5B1%5D.jpg)

A European Defense Industrial Strategy (EDIS) was presented after the aggression against Ukraine. The strategy is intended to encourage investments,...