Industry 4.0: The foundation of everything we do

The ceaseless progression of technology stops for no one - and the industrial landscape makes no exception. With the booming transformation that the...

2 min read

Multicut Blog Author : Jul 5, 2022 2:42:00 PM

Greentech is booming – new technologies emerge all the time to use tech to reduce human impact on the climate. Everything from wave energy to CO2-reducing innovations in ship engines; all over the globe innovative companies think up new ways to use resources better and reduce our footprint.

But there is a long way to go from the invention of a gizmo to full-scale manufacturing of thousands or even millions of the same product. What should innovators do when the time comes to scale the production?

In the seventies, wind energy was breaking new ground. The technology in wind turbines underwent an explosive evolution, and wind energy tech went from being something being built from scrap metal by hand to a global mega-business.

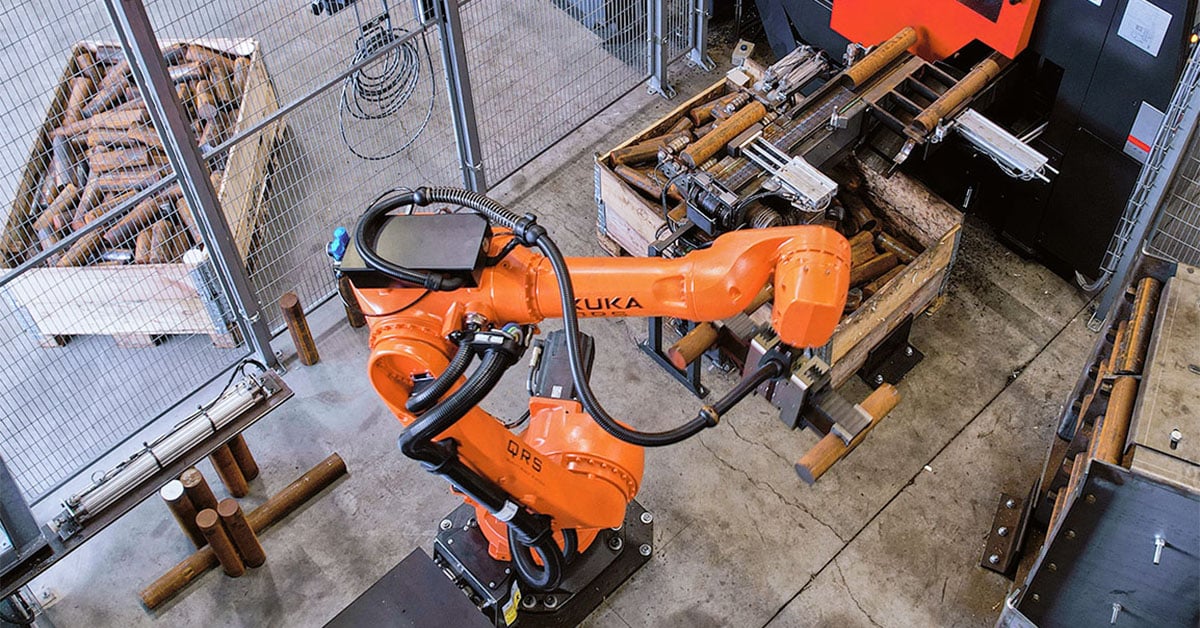

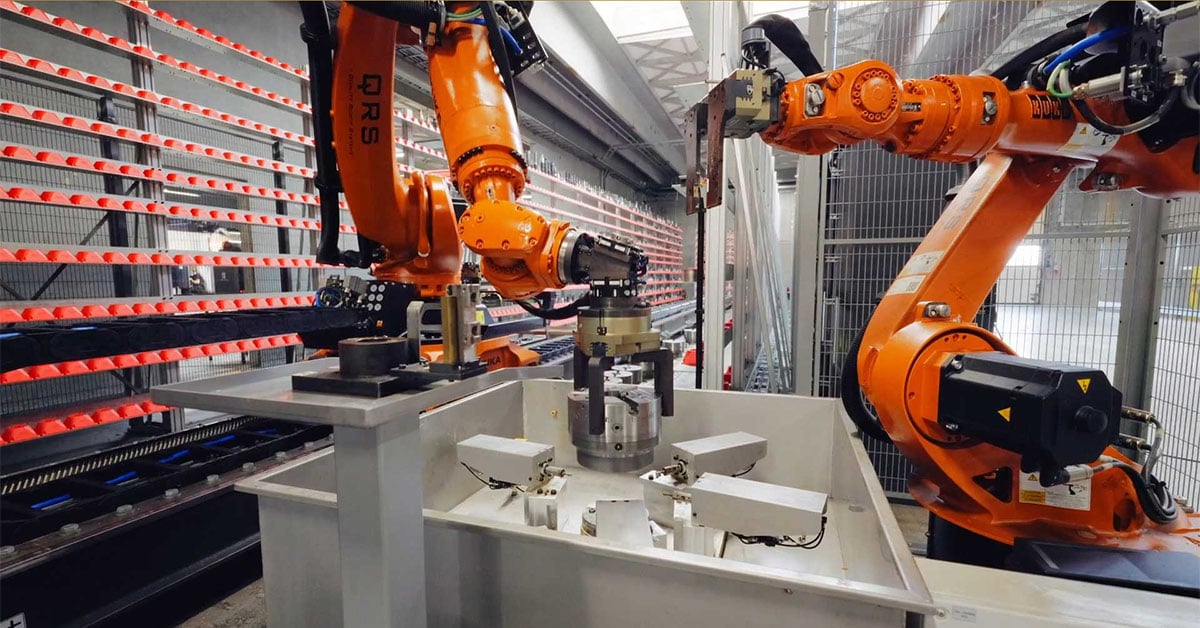

Wind turbines went from being small structures with simple technology to being enormous constructions with wing tips reaching hundreds of meters into the sky – most of them placed far off-shore. In a modern 3 MW offshore wind turbine, just to give you an example, each wing is fitted to the hub by studs known as bushings – 180 for each wing. That’s 540 metal studs for each turbine, and each is turned to very exacting standards and very low tolerances.

For wind turbine manufacturers such as Vestas, the ramp-up from prototype bushing to continuous production of thousands of identical pieces each month is business-critical, even though these bushings are just a small part of a giant structure.

Consequently, for Vestas, finding the right supplier is not just a question of quality, documentation, testing, logistics, and component price – scalability plays a major role. Most small or medium-sized machine shops can make a bushing to meet very high standards. They’re not exactly complicated products.

The challenge comes when production runs from a few hundred to several thousand or even hundreds of thousands. The small machine shop will not be able to cope. Vestas knows this and will only approach a supplier with the capacity to ramp up when needed.

Wind energy is no longer considered Greentech in the strictest sense of the word – it’s now an established part of the world’s energy supply, and the technology is mature.

Businesses, governments, and organizations are increasingly beginning to open their eyes to environmentally friendly technologies as more attention has been paid to the negative impact of humans on the planet. Consider such things as buying locally – at some point in the future, someone is going to ask you about your carbon footprint. Shipping stuff from across the globe may not be in your best interest.

In the world of Greentech, new technologies emerge all the time – with components that have perhaps never been machined before. For inventors and innovators, the idea of having to produce vast quantities of their prototype may seem like something that’s far off in the distant future.

One day, if all goes well, that future becomes the present – and then what? We recommend that you team up with producers with scalability as soon as possible in the process of your development.

The ceaseless progression of technology stops for no one - and the industrial landscape makes no exception. With the booming transformation that the...

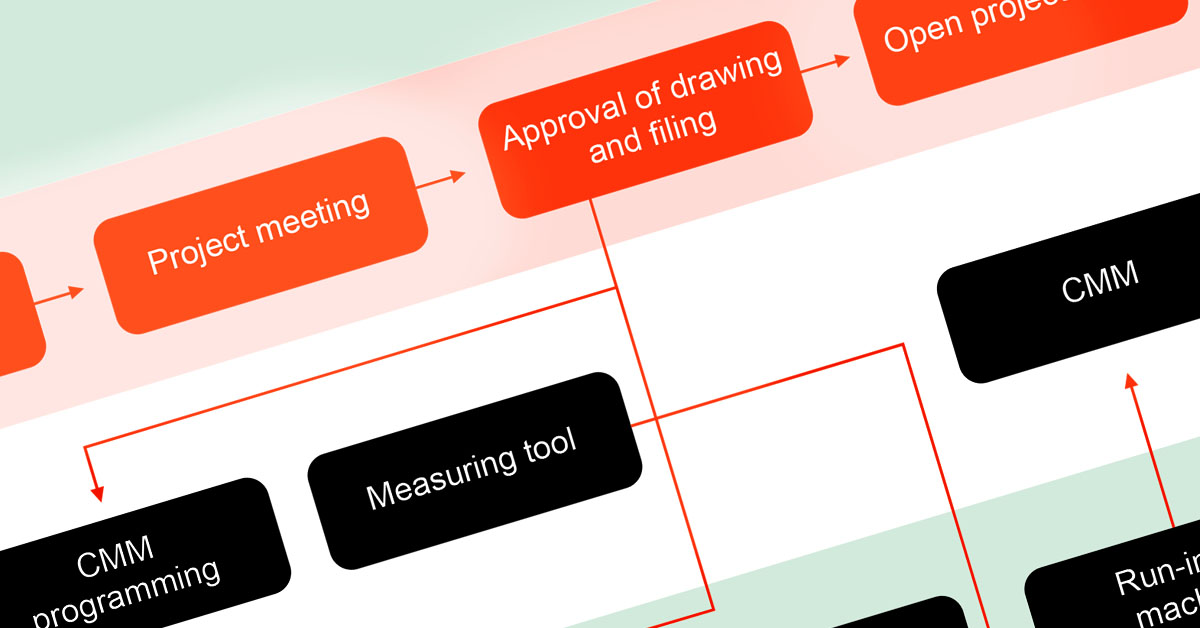

In an industry where punctuality and timeliness are crucial, there is no room for mistakes. When Multicut forms part of any supply chain, we always...

Working closely with the heavy-weights in the defense industry, employing a thorough New Product Implementation-process (NPI) is your guarantee for...